Skid process equipment

The company has developed expertise in several industry sectors, among other things thanks to specialized partners. NXT is a certified integrator of several innovative companies like 3M, Haffmans, Sudmo, etc. With the design and engineering of this equipment already completed, NXT has manufactured some of its equipment and are making it available for testing or rental.

Equipment

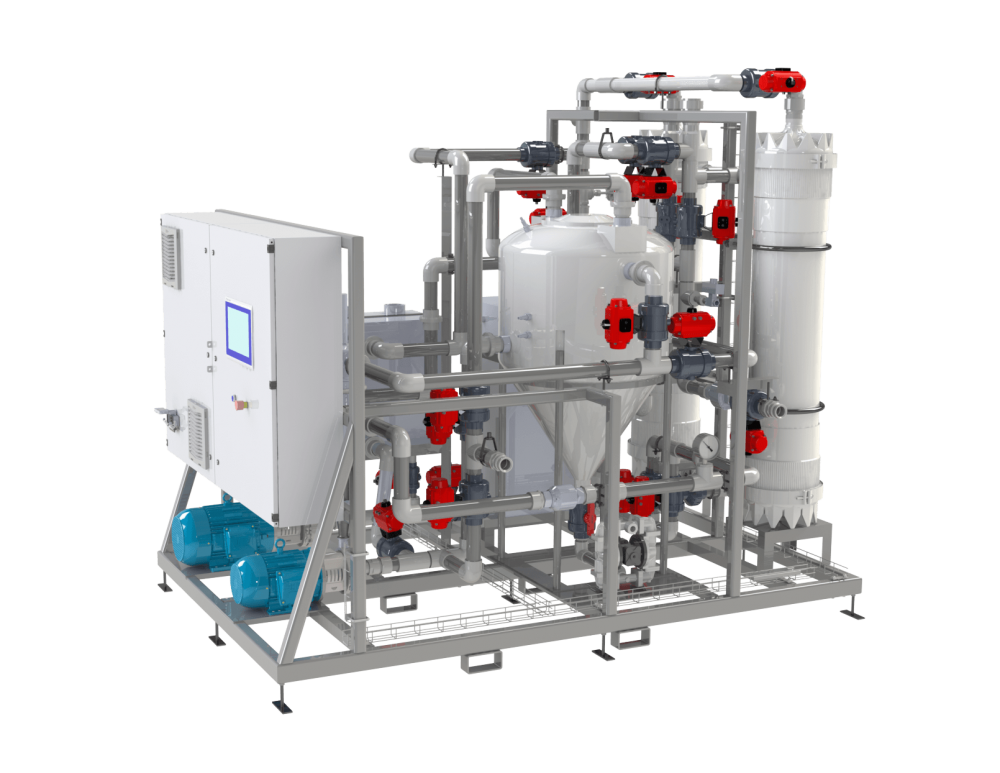

DEOX SYSTEM

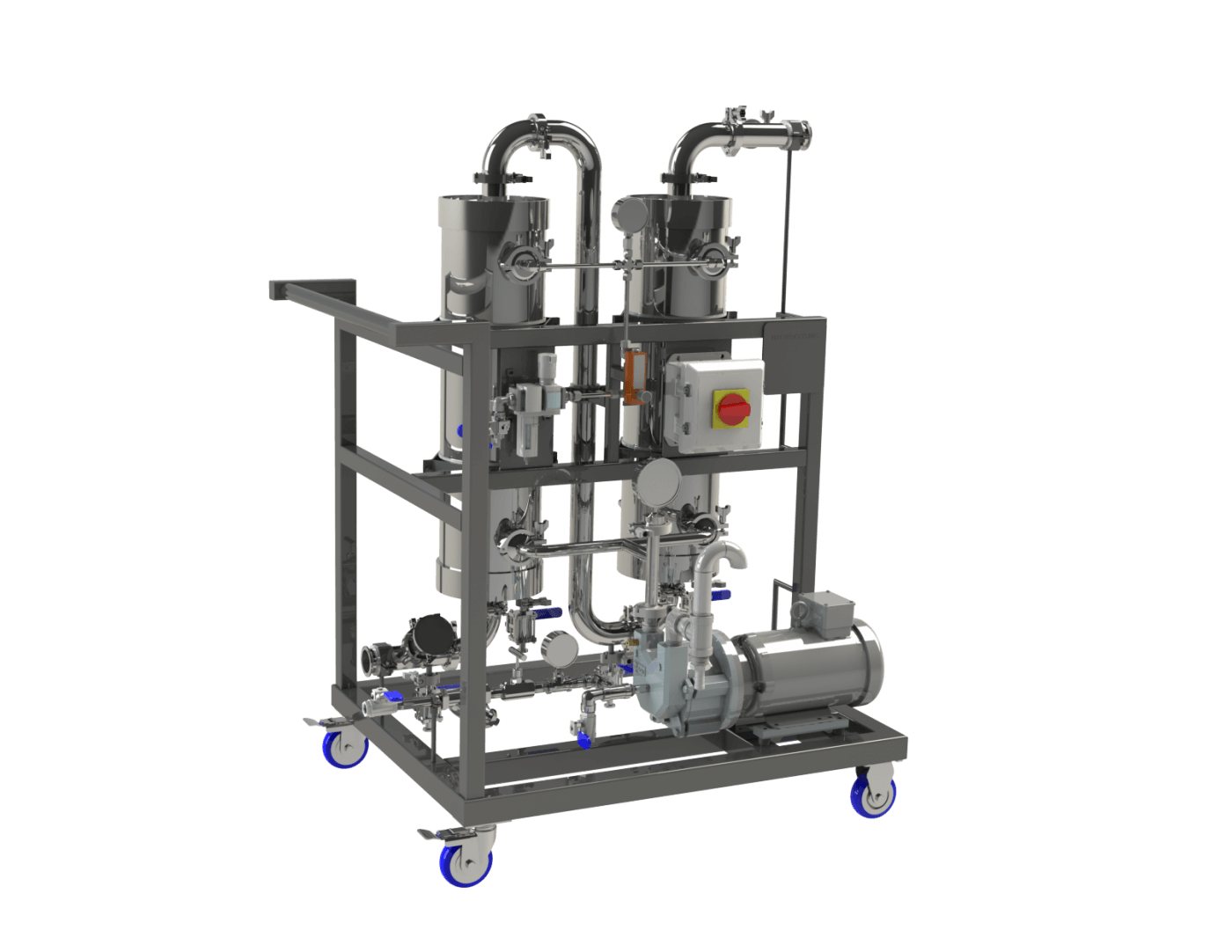

The NXT DEOX deoxygenation system using Liqui-CelTM membrane contactors can be installed directly on the production line. For process water flowing at 60 hl / h (~ 26 gpm), two Liqui-Cel EXF8x20 membrane contactors arranged in series are required to remove almost 100% of the dissolved oxygen. A centrifugal pump can be added upstream of the system if necessary. A vacuum pump is used to create a pressure gradient which allows for better oxygen extraction. Measuring instruments make it possible to know the properties of the process water entering and leaving the deoxygenation system, particularly the oxygen sensor, which validates the performance of the system

Deaerated water is used in the production of non-alcoholic beer, high-gravity brewing and also seltzers. It allows the water to be mixed into the drink without creating oxydation. Oxygen-free water can also be used to do water push without leaving traces of oxygen in the tanks and piping.

NXT DEOX SYSTEM

MAIN FEATURES

- In-line deoxygenation for liquid at temperature between 8 ° C and 20 ° C

- CIP able

- Allows you to remove almost 100% of the O2

- Available for purchase and rental

- Centrifugal pump addition option

TECHNICAL SPECIFICATIONS

| O2 withdrawal capacity | 99.71% |

| N2 withdrawal capacity | 71.15% |

| Motor | - - |

| Pump | - - |

| Connections | 2 ’TC, other connections available on request |

| Materials | SS 304, SS316 |

| General dimensions | 62 ‘’ X 43’’ X 30’’ |

LOOKING FOR A SYSTEM?

You did not find an equipment ? You might find it in our Systems section