Custom made systems for your projects

We undertake the conception through the fabrication of each systems. Our systems are designed according to the specific needs and requirements of each client.

systems done one step at a time

All NXT Process systems are originally designed to meet the standards of the industry in which the system will be installed. Each stage can be broken down and quoted separately.

Deliverables

- Customized design according to the process need

- Mechanical design based on available space

- Electrical design

- Automating

- System manufacturing

- On-site installation of piping and electrical connection (optional)

- System start

- Training

Systems

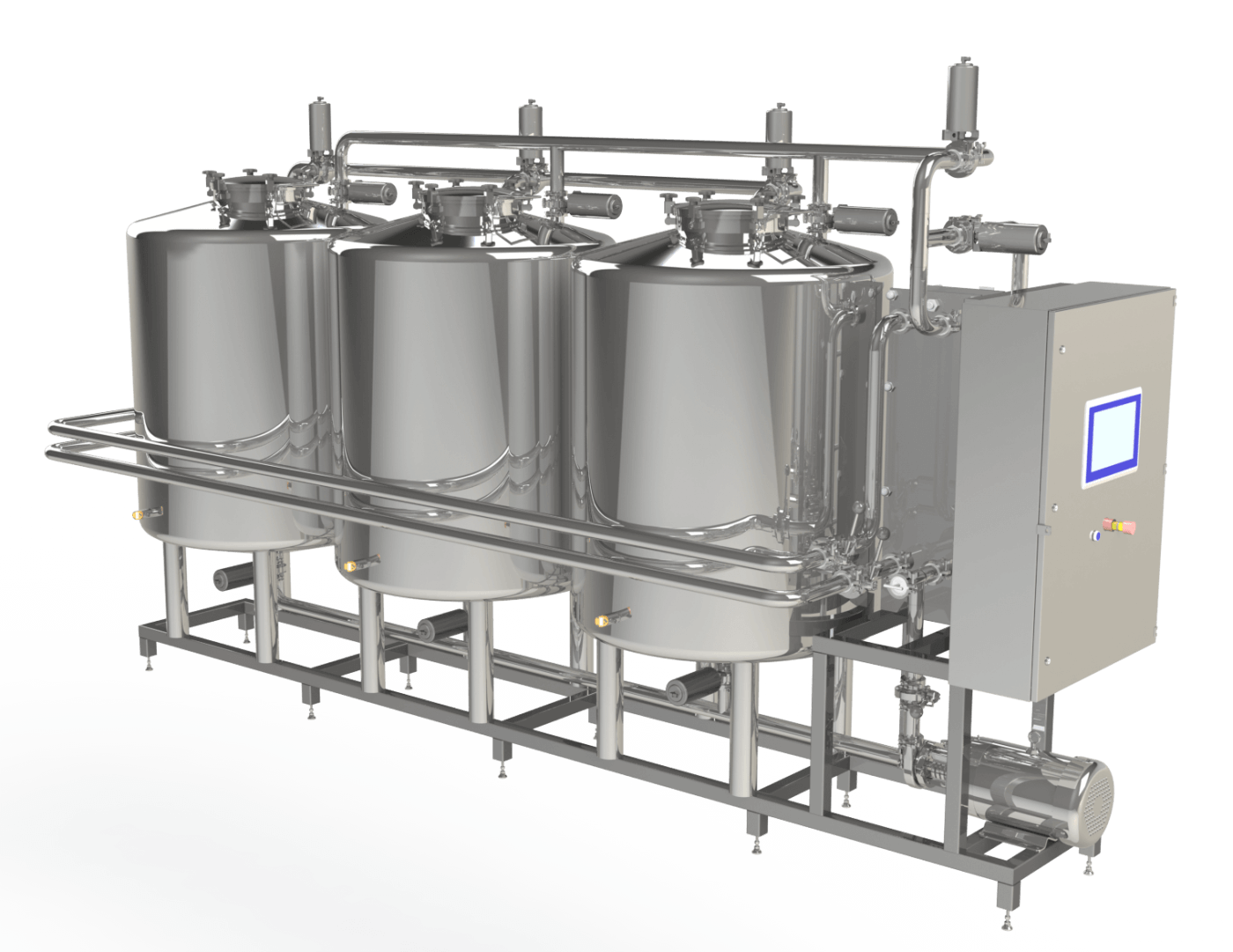

Clean-in-place system

CIP (CIP) is a method of sanitary cleaning of process lines, vessels and equipment commonly used in the plant. The process involves circulating a cleaning fluid through piping and equipment. Unlike Room Cleaning (COP), CIP does not require disassembly or relocation of equipment.

Temporary image

Specifications and Capacity

- 304 or 316 stainless steel

- Mobile system from 100 liters to 300 liters

- Fixed system from 300 liters to 10,000 liters

- Our systems are designed to be manual or automatic

- Adjustable legs

- Meets 3A standard

Options

- Automatic dosage for 1 to 3 products

- System of 3 to 5 tanks

- Plate, tube or electric heat exchanger

Industries served

- Industrial (chemical)

- Food

- Brewing

- Pharmaceutical

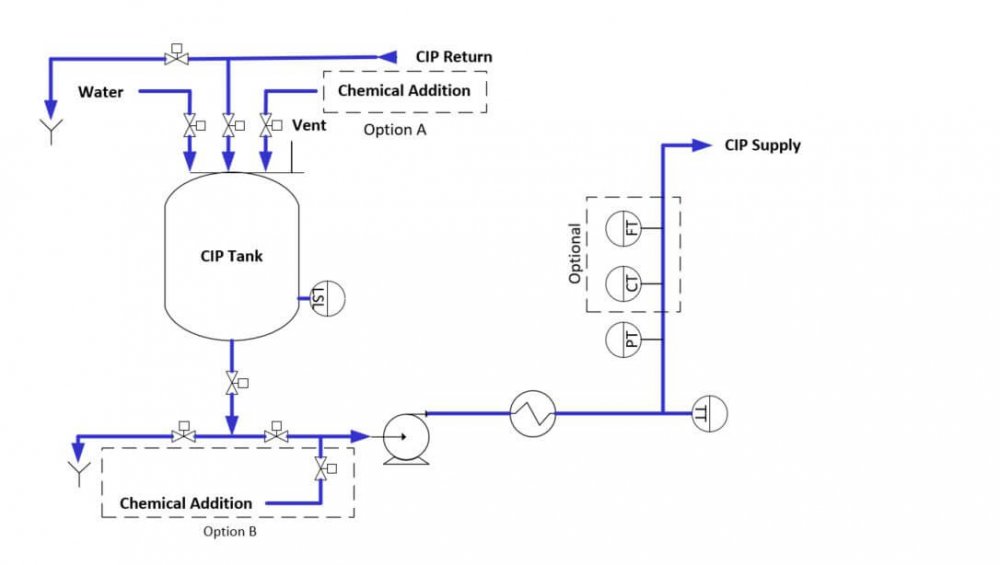

Simple tank process

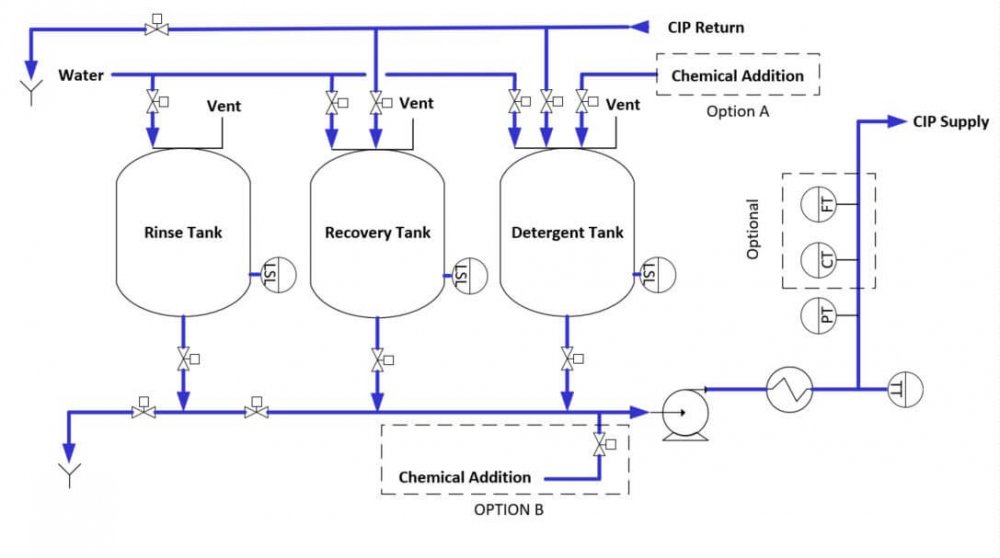

3-tank process

Looking for a frame mounted equipment?

Visit our EQUIPEMENT page for all of skid mounted and mobile products