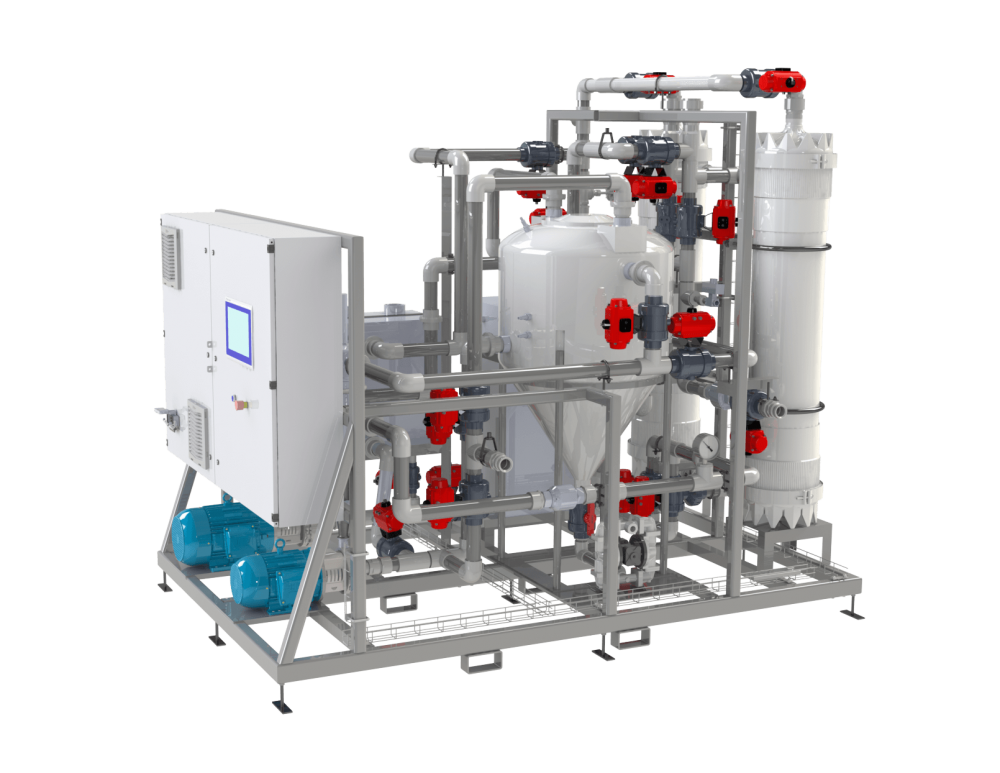

Skid process equipment

The company has developed expertise in several industry sectors, among other things thanks to specialized partners. NXT is a certified integrator of several innovative companies like 3M, Haffmans, Sudmo, etc. With the design and engineering of this equipment already completed, NXT has manufactured some of its equipment and are making it available for testing or rental.

Equipment

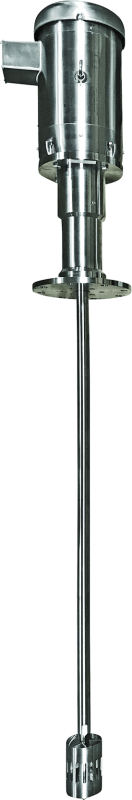

JET-Shear In-Tank Mixer

The JET-Shear in-tank mixer manufactured by Ampco Applied Products (AAP) is the go-to technology to efficiently and consistently emulsify, dissolve, disperse, homogenize and hydrate solid ingredients (powders and particles) within your process. Equipped with impellers at the top and bottom of the work head to draw in material while centrifugal force moves the media out creating a mechanical shear, you will reduce the processing time, increase quality and consistency of the blend. The multiple interchangeable stainless steel work heads are designed for 3A and CIP all while being compatible with open and closed tanks, drums or totes.

JET-Shear In-Tank Mixers

Available Models

JS125

| Max Shaft Length | 48" |

| Standard Shaft Diameter | 1.25" |

| Workhead Diameter | 2.5"-4.0" |

JS150

| Max Shaft Length | 60" |

| Standard Shaft Diameter | 1.50" |

| Workhead Diameter | 3.5"-4.0" |

JS200

| Max Shaft Length | 84" |

| Standard Shaft Diameter | 2.00" |

| Workhead Diameter | 3.5"-4.5" |

JS225

| Max Shaft Length | 84" |

| Standard Shaft Diameter | 2.25" |

| Workhead Diameter | 4.5"-6.0" |

JS300

| Max Shaft Length | 96" |

| Standard Shaft Diameter | 3.00" |

| Workhead Diameter | 5.0"-8.0" |

JS400

| Max Shaft Length | 96" |

| Standard Shaft Diameter | 4.00" |

| Workhead Diameter | 6.0"-10.0" |

Mounting Options Available

Various Work Head Options to Maximise Efficiency for:

- Mixing

- Dispersing

- Hydration

- De-agglomeration

- Particle Size Reduction

- Emulsification

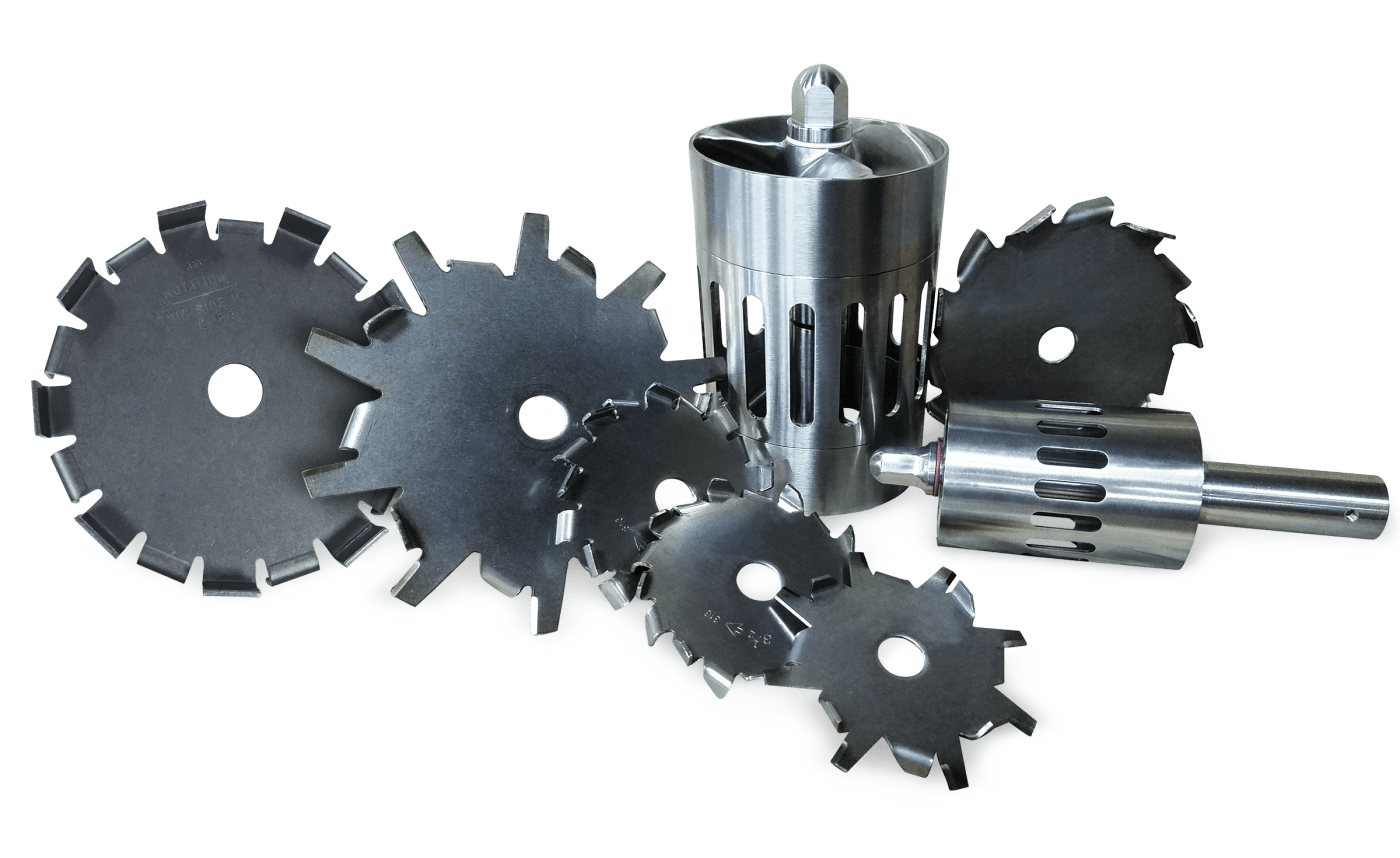

Work Head Options

LOOKING FOR A SYSTEM?

You did not find an equipment ? You might find it in our Systems section