Custom made systems for your projects

We undertake the conception through the fabrication of each systems. Our systems are designed according to the specific needs and requirements of each client.

systems done one step at a time

All NXT Process systems are originally designed to meet the standards of the industry in which the system will be installed. Each stage can be broken down and quoted separately.

Deliverables

- Customized design according to the process need

- Mechanical design based on available space

- Electrical design

- Automating

- System manufacturing

- On-site installation of piping and electrical connection (optional)

- System start

- Training

Systems

CO2 Recovery System

It is possible to recover the CO2 generated during fermentation and re-inject it before canning.

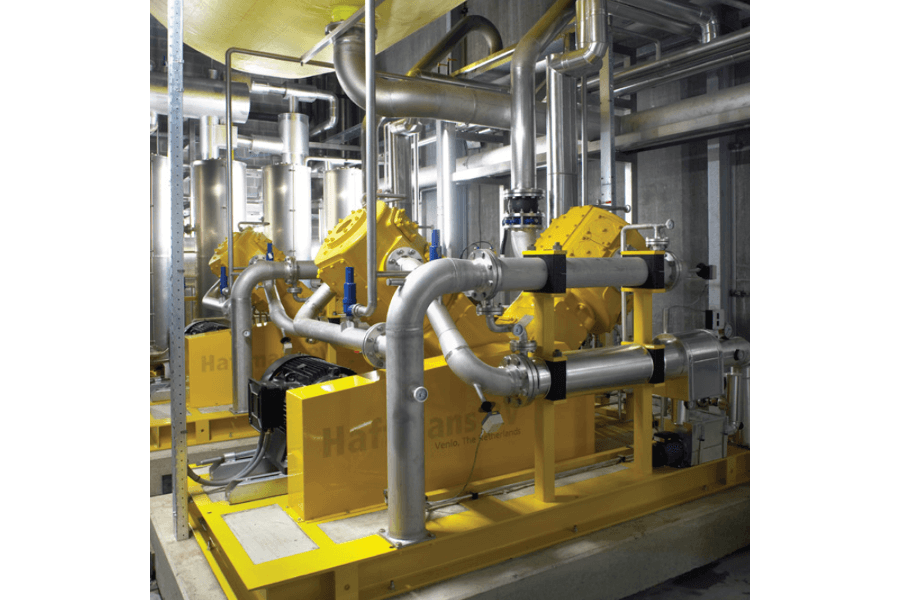

The process of CO2 recovery begins with a foam separator which drains the foam from the incoming gas. The gas is then purified, compressed and liquefied for storage in cryogenic tanks outside.

Pentair Haffmans efficiently recovers CO2 from various sources providing foodgrade CO2 that meets the highest quality standards in the industry. Designed to meet each customers specific situation, the state-of-the-art CO2 recovery solution offers the lowest production costs per liquid CO2 tonne

Benefits

- Foodgrade CO2

- High purity: CO2; 99.998% v/v, low O2t; 5 ppm v/v

- Up to 60% energy reduction

- Fully automatic operation

- Compact skid mounted design for quick installation

- Experienced technical support

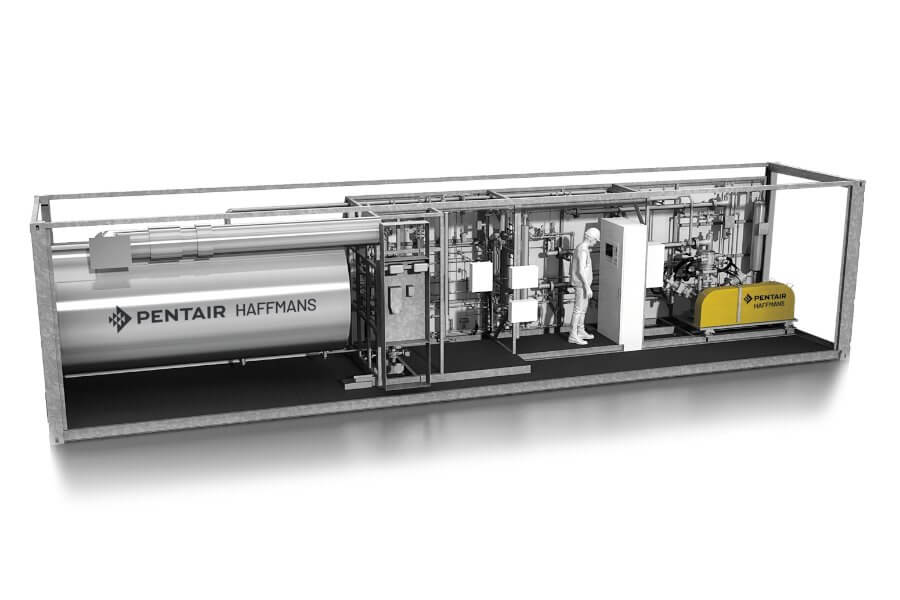

CO2MPACTBREW

ECO2BREW

CO2 RECOVERY UNIT (CRU)

CO2MPACTBREW

CO2mpactBrew is a CO2 recovery plant especially designed for smaller, craft-sized breweries to ensure a continuous and self-sufficient supply of beverage-grade quality CO2.

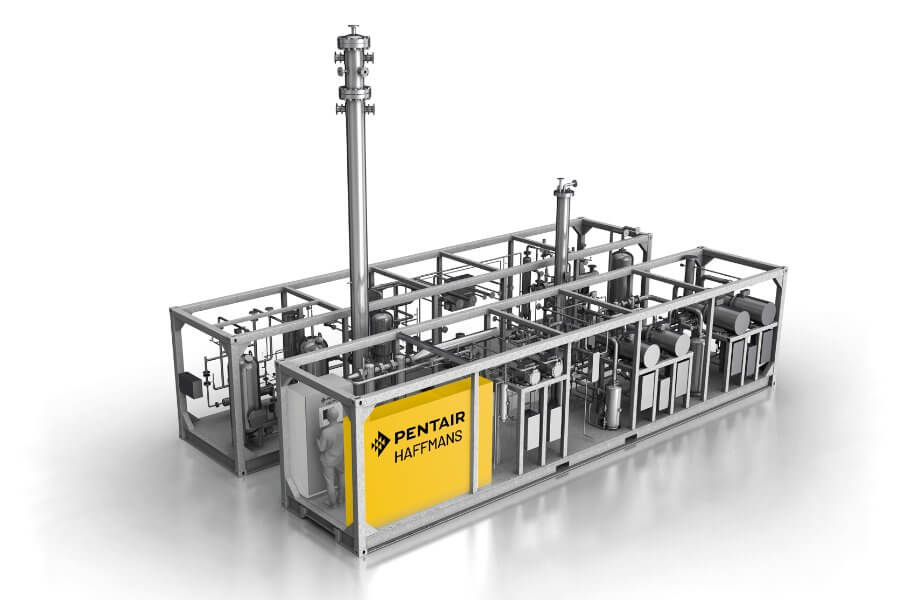

ECO2BREW

ECO2Brew is unique in its design to recover CO2 from fermentation processes at larger 24/7 operating breweries (> 2,000,000 hl/yr). Its 100 % water-free operation can save up to 1 m3 of water per tone liquid CO2 in tank.

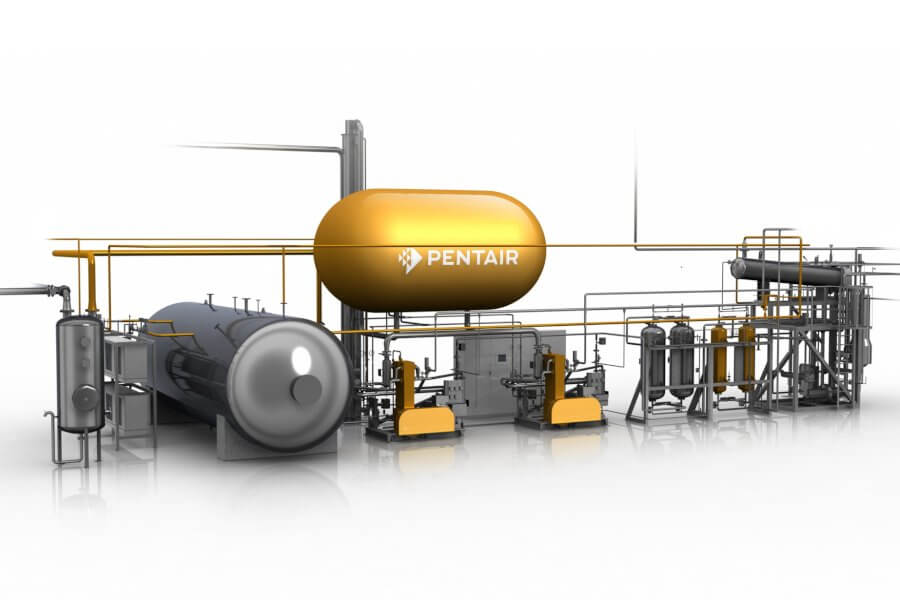

CO2 RECOVERY UNIT (CRU)

CO2 Recovery Unit (CRU) is a robust and reliable CO2 recovery solution for a wide variety of brewery needs ranging from 300,000 to beyond 5,000,000 hl/yr. It is the benchmark CO2 recovery plant in the global brewing industry with 25-year-old plants still running strongly.

Looking for a frame mounted equipment?

Visit our EQUIPEMENT page for all of skid mounted and mobile products